Packing Method: 1.In bundle 2.Wrapping Film,plastic tape, Plywood pallet. 3.Plywood Pallets is optional for wire basket cable tray 4.Carton for accessories 5.As per requirementsOverview of PHQ- high strength whisker modified plastic cable supporting systemWhisker calcium carbonate is a micro/nano short fiber grown from a single crystal of high purity. Its mechanical strength is equal to the strength generated by the adjacent interatomic force. The highly oriented structure of whisker not only makes it high strength, high modulus and high elongation, but also have properties of electricity, light, magnetic, dielectric, conductive and super-electric . The strength of whiskers is much higher than that of other staple fibers. The growth whisker mainly used for composite materials can be divided into organic whisker and inorganic whisker. Inorganic whisker includes calcium sulfate and calcium carbonate, which are applied in the field of polymer composite materials.

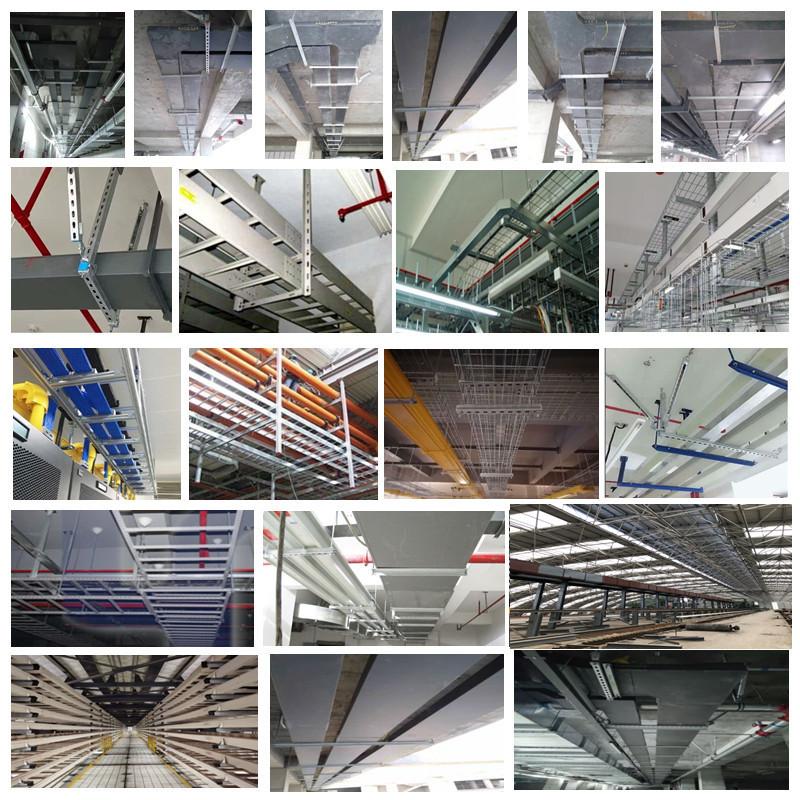

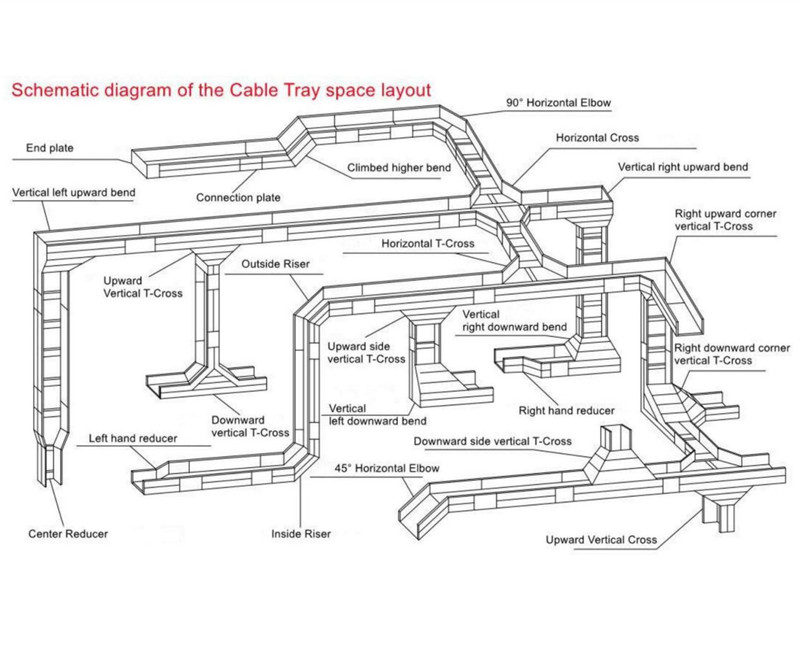

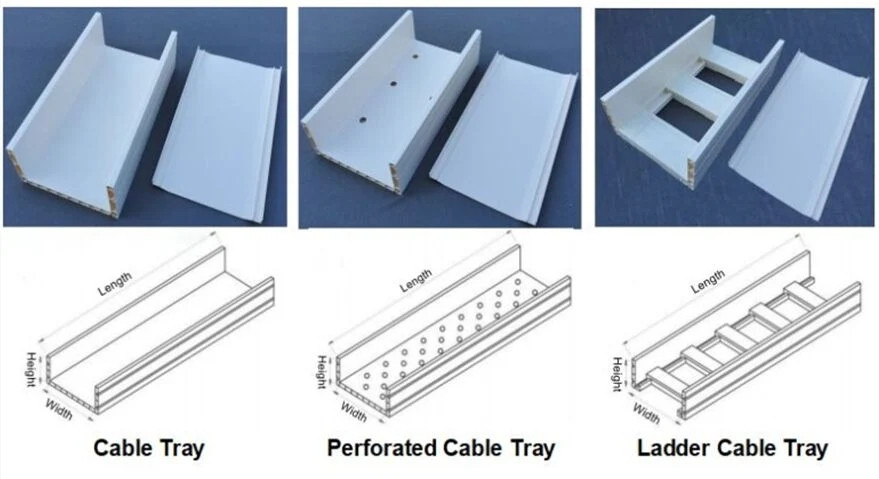

Perforated Cable channels are usually used for exposed wiring systems. The selection principles are as follows: A: channel wiring is not suitable for cables bearing large current, because of their poor heat dissipation performance, the factor of cable capacity reduction performance should be considered; B:When bunching of cables are laid in the ceiling, closed cable channels or trays should be used to improve fire-prevention performance. C: when power cables and communication cables with combustion performance classification of Bl which are laid within the closed space of Bl level or cable tray , they can be laid in the stuffy ceiling or suspended ceiling without combustible material of grade Bl in . Scope of application: Polymer alloy cable tray is suitable for laying power cable, control cable, computer cable, lighting wiring, indoor and outdoor overhead, cable trench, cable tunnel, petrochemical, power, construction and other fields. Three innovations: 1. Formulation and process innovation: high impact strength, good dimensional stability and excellent corrosion resistance. 2. Innovation of preparation process: twin screw extrusion process and ASA double-layer co extrusion process are adopted to make the product plasticizing and mixing effect good. 3. Product structure innovation, double hollow structure design, light weight, easy heat dissipation and enhanced bearing capacity. Q: Are you a factory or a trading company? A:We not only have our own factories but also have shares in some other enterprises. Q:What services you can offer? A:We are manufacturer with a range of electrical and network cable tray systems , you can enjoy the one-stop shopping service from our company.Quality and cost driving manufacturer with ISO9001,CE,NEMA,UL,SGS certificated to provide customers reliable products with most competitive price. Q:How can you make commitment passing the test? A:We have professional lab to do below test: a.safe loading test b.galvanized thickness test c.salt spray test d.electrical continuity Q:What is your products advantages: A: a.Reduce installation costs and time b.Easy for changing, adding and moving c.Bright surface means good material and quality d.Our electrical and network cabling equipment have the same quality as the international famous brand. Q: Can you provide samples? A: Yes ,you can get the free samples. Q: What is your payment terms? A: 30% T/T deposit,balance will be paid before shipment or against the copy of B/L; Q: How about the delivery time? A: According to your order list and quantity,Normally delivery in 15-25days. Q: Why do choose us? A: Cable Tray Official Certificates Worldwide We has been certified by ISO9001 in China, UL in U.S.A and CE in E.U. with professional design and extremely well production techniques. These certifications are our first step into the International market. Cable Tray Production Flow Strictly Managed Our Factory has various types of CNC machines, high quality modeling machines, processing equipment, which provides the most powerful guarantee for high quality products. Cable Tray Quality Traceability System Maintained In order to serve high quality products, it is essential to test the manufactured products before delivery. In this session, Our factory develops the most stringent testing procedures, and trains factory inspectors besides its already high level product inspection equipment. | Ordering Code | Specification |

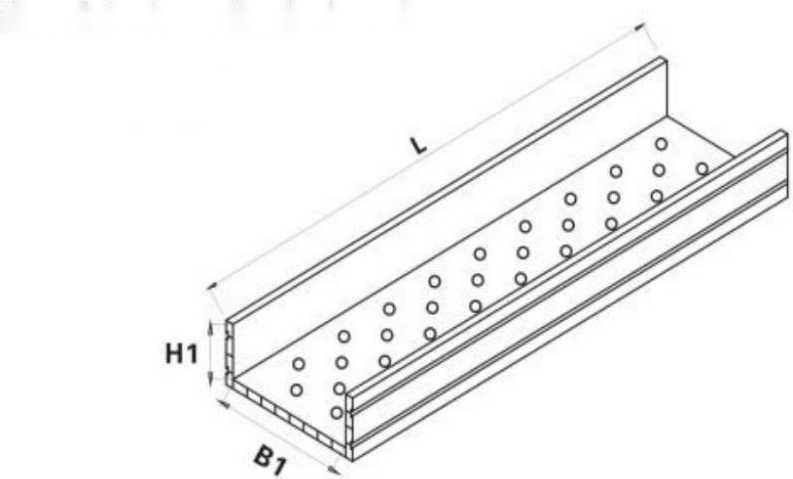

| B1(mm) | H1(mm) | L(mm) |

| PHQ-K-1A | 50 | 50 | 3000 |

| 100 | 50/100 |

| 200 | |

| 300 |

| 400 |

| 500 |

| 600 |

| 800 |

| 1000 |

| 1200 |

Three innovations: 1. Formulation and process innovation: high impact strength, good dimensional stability and excellent corrosion resistance. 2. Innovation of preparation process: twin screw extrusion process and ASA double-layer co extrusion process are adopted to make the product plasticizing and mixing effect good. 3. Product structure innovation, double hollow structure design, light weight, easy heat dissipation and enhanced bearing capacity.