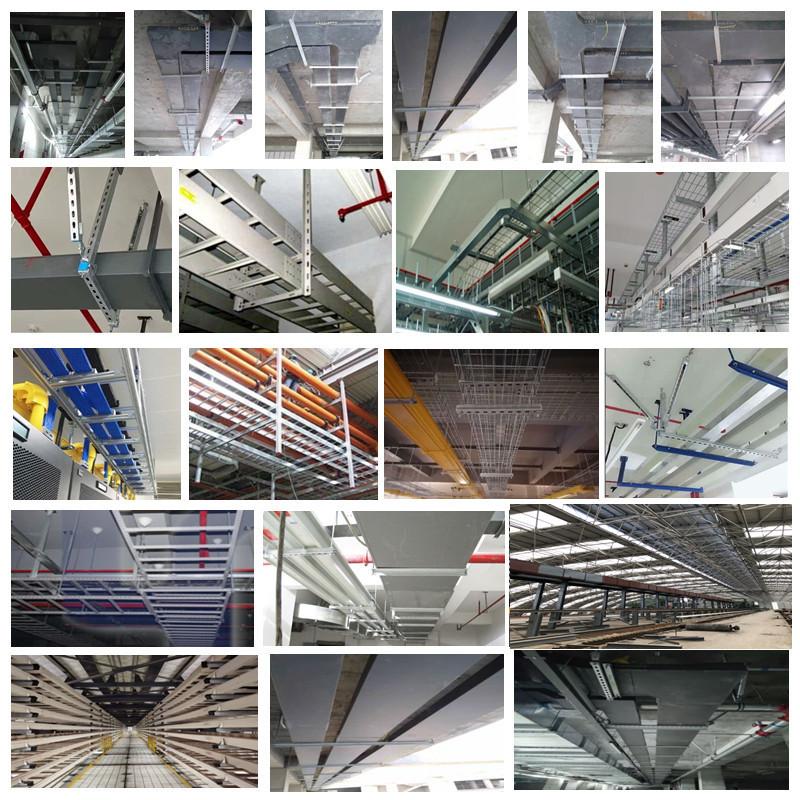

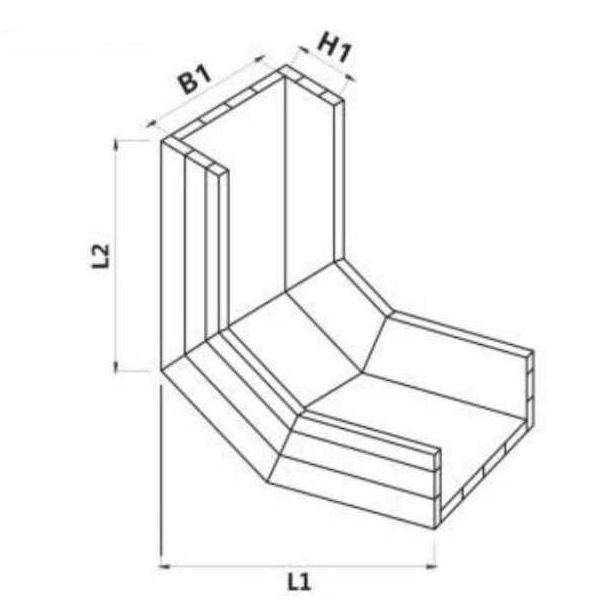

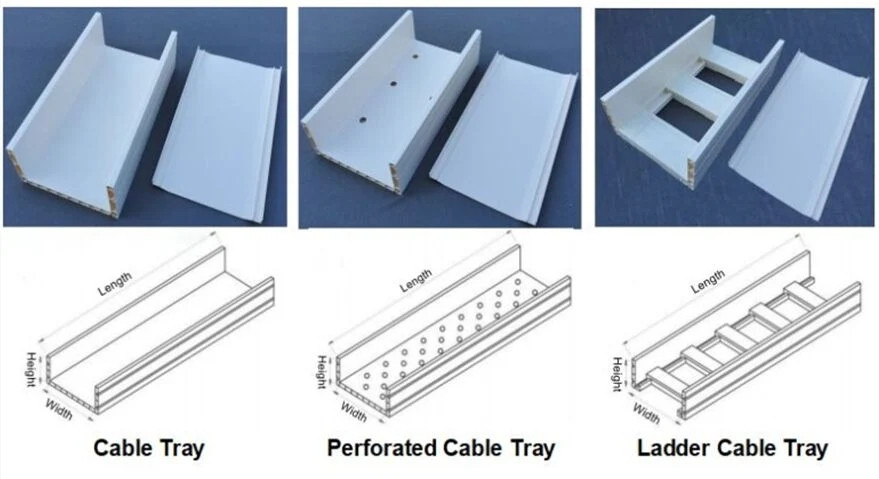

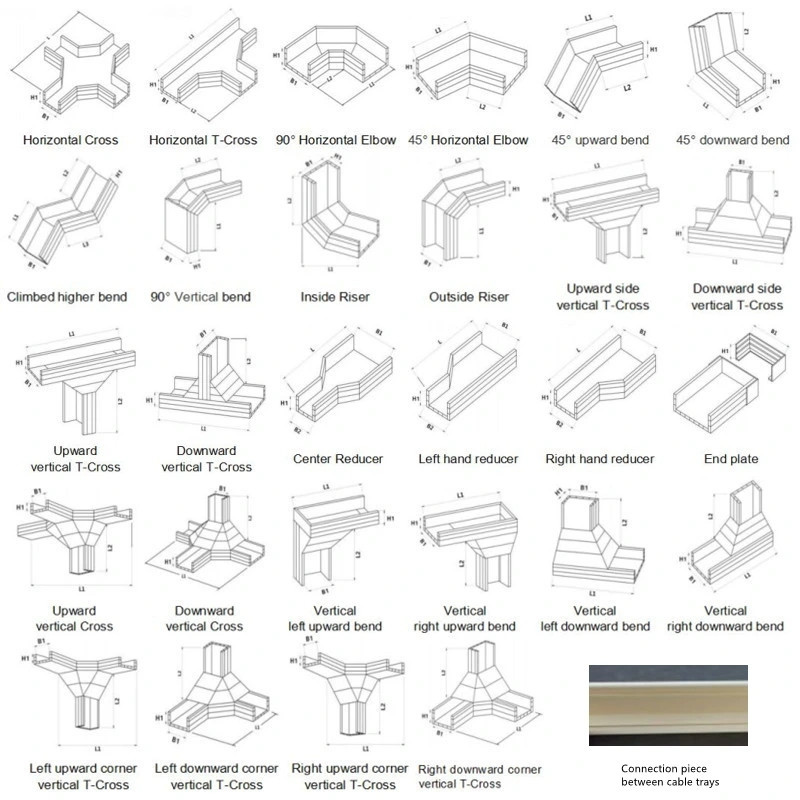

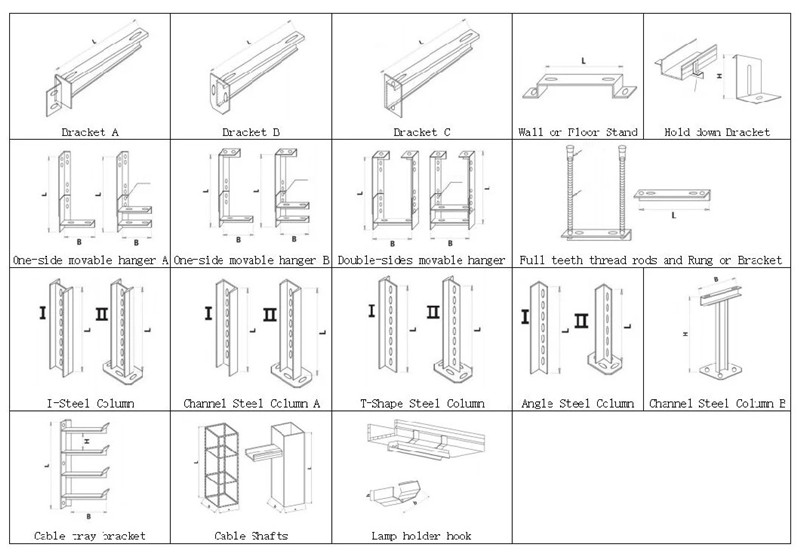

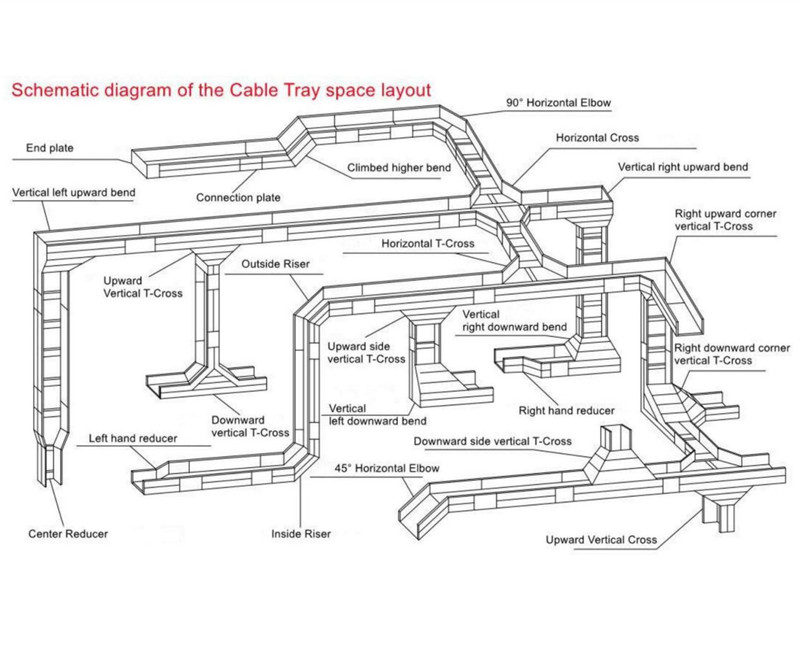

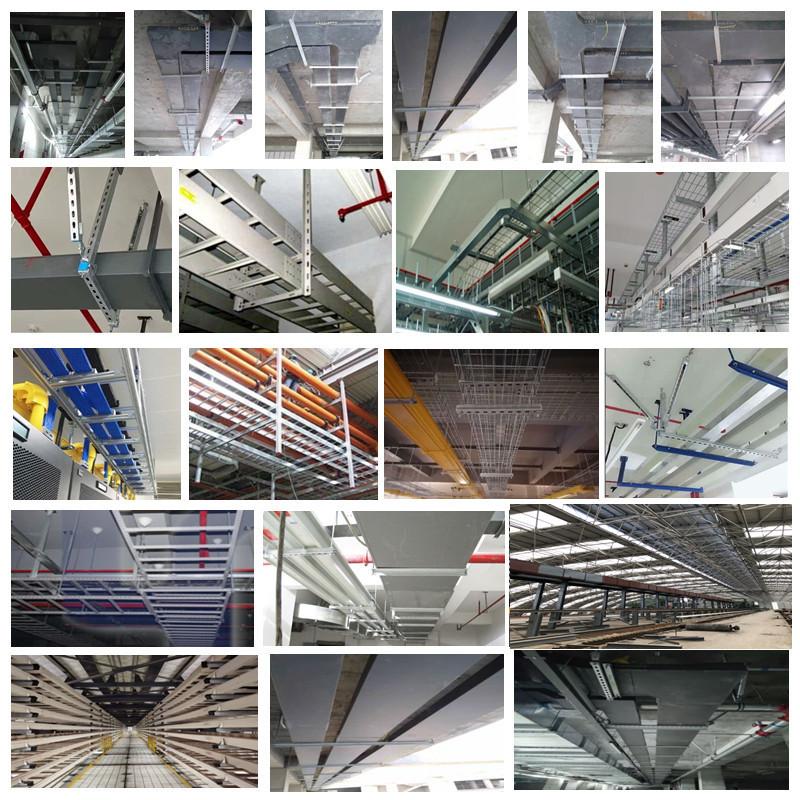

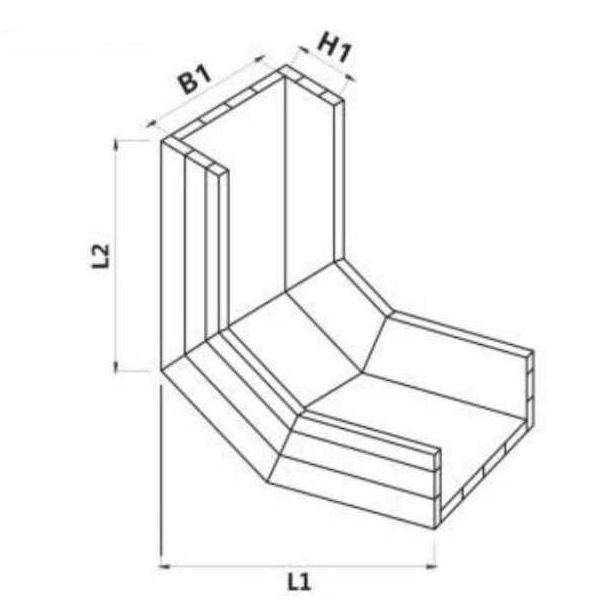

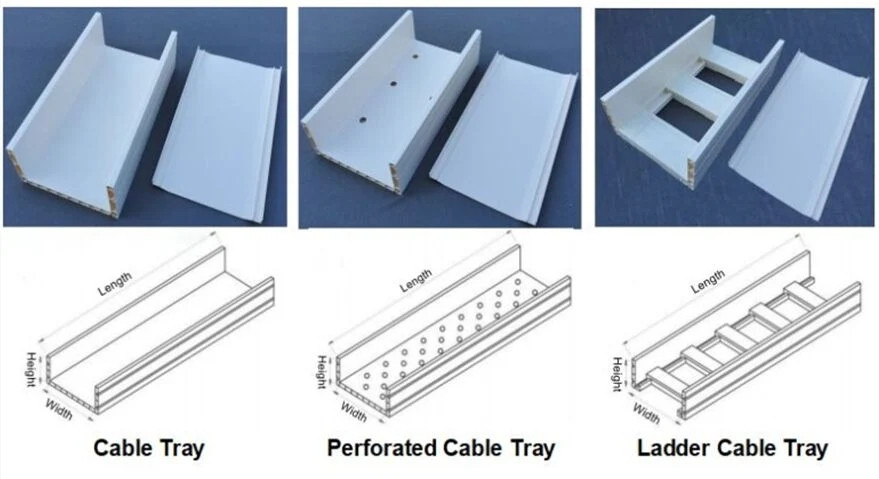

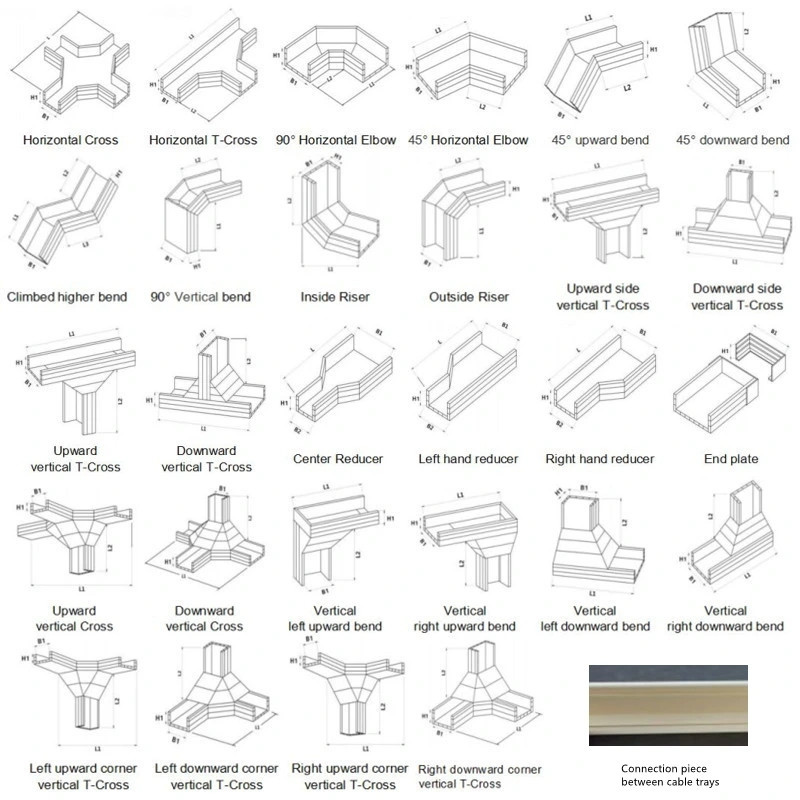

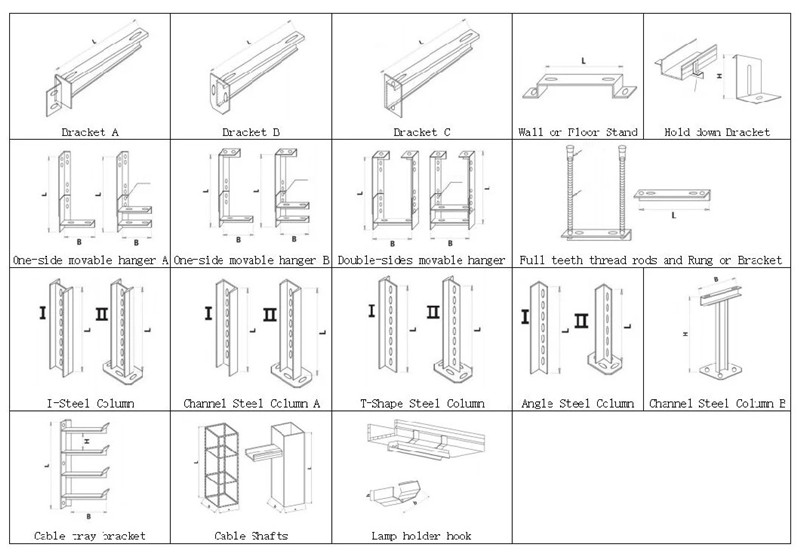

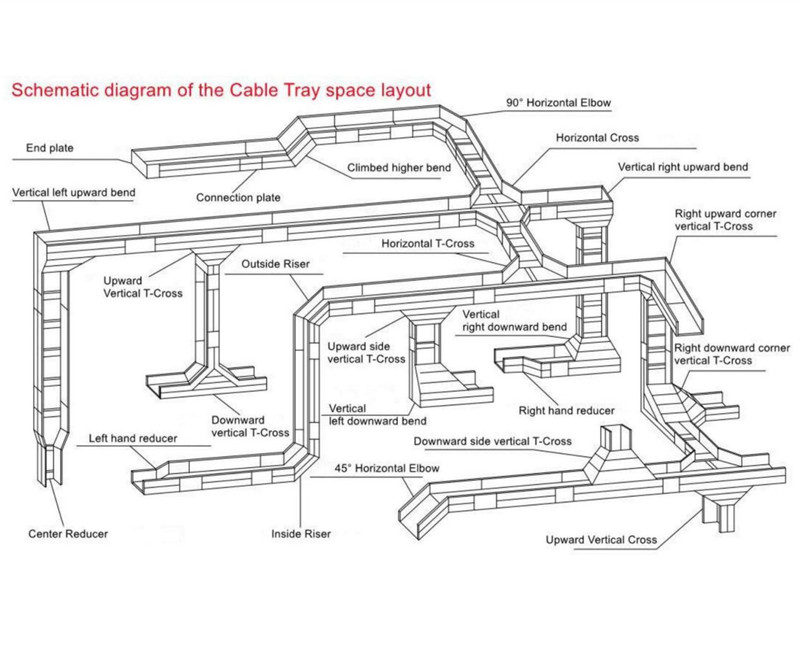

Cable supporting system consists of cable ladder, cable tray and cable channel. According to the manufacturing materials, it is divided into metal bridge and plastic bridge, glass fiber reinforced plastic bridge etc. According to the structure, it is divided into cable ladder, cable tray, cable channel ,they each has its advantages and disadvantages: the ladder frame has good ventilation performance, but not dust-proof or interference, channel type has dust-proof, anti-interference, but the heat dissipation performance is poor. Slotted cable tray is mainly used for exposed wiring in industrial and civil buildings. Each kind of cable supporting system is comprised of straight through parts, bends components , strut channel, connectors and fittings. Inside Riser 90°is one of the bend components usually used for climbing bend 90°.