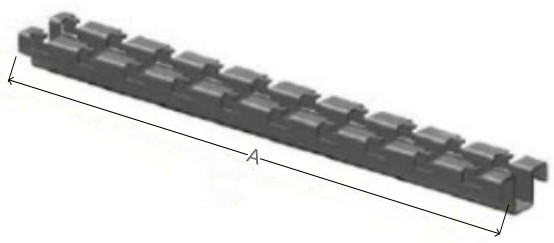

| Ordering Code | W(mm) | A(mm) | |

| HM-SB | HM-SB-50 | 50 | 150 |

| HM-SB-100 | 100 | 200 | |

| HM-SB-150 | 150 | 250 | |

| HM-SB-200 | 200 | 300 | |

| HM-SB-250 | 250 | 350 | |

| HM-SB-300 | 300 | 400 | |

| HM-SB-450 | 450 | 550 | |

| HM-SB-600 | 600 | 700 | |

| Ordering Code | W(mm) | A(mm) | |

| HM-SB | HM-SB-50 | 50 | 150 |

| HM-SB-100 | 100 | 200 | |

| HM-SB-150 | 150 | 250 | |

| HM-SB-200 | 200 | 300 | |

| HM-SB-250 | 250 | 350 | |

| HM-SB-300 | 300 | 400 | |

| HM-SB-450 | 450 | 550 | |

| HM-SB-600 | 600 | 700 | |